A new invention byNASAscientists acts like a “sensory skin,” picking up signs of damage to spacecraft exterior in real time.

If it proves successful, the technology could be applied to satellites, aircraft, and even otherworldly habitats — such as a human-built structure on the lunar or Martian surface — in the future.

Damage Detector At Work

Orbital debris as well as micrometeoroids hurtle toward spacecraft at speeds of 17,5000 miles per hour just in low-Earth orbit, or more than 24,000 miles per hour for lunar and deep space trips. This could pose threats to the physical structure and integrity of spacecraft.

Remember thespace junk debristhat hit the cupola of the International Space Station last year and caused a tiny window crack? An image showed a 7-millimeter (0.28-inch) circular chip with potentially a paint flake or tiny metal fragment, with the eerie blackness of space serving as the crack’s background.

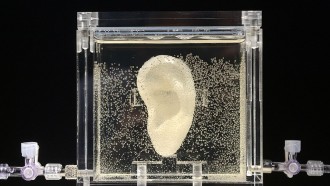

The recent NASA innovation seeks to address issues like this and worse others. It uses a series of several technologies to form circuits printed on thin layers and that can be integrated in the spacecraft structure.

"It's a sensory system that tells us where we are damaged and the level of intensity,”sharedMartha Williams, who leads the development team of the technology dubbed the Flexible Damage Detection System currently being developed at NASA’s Kennedy Space Center in Florida.

Once something pierces a space vehicle’s hull, composed of the first layer or two, current capabilities offer passenger-astronauts limited ways to detect damage. These methods at present require a camera check or an astronaut’s spacewalk in order to see and analyze the damage, unless a leak occurs and sets off alarms as an impact penetrates all the way through the spacecraft.

This new “sensory skin,” as Williams called it, boasts various systems ranging from low-voltage electrical circuits printed on Kapton thermal insulation film to damage-tracking software.

Potential For Commercial Production And Related Uses

The scientists are seeking to make the Flexible Damage Detection System's manufacturing so efficient that the technology can be replicated for commercial production and use.

On the ground, scientists as well as engineers demonstrate a 6-by-6-inch sensory panel connected to wires and a monitoring computer system. They seek to tile the square pieces together - like in a quilt - to form a solid sensor network, which could also be foldable and functional in expandable or inflatable spacecraft.

A tailorable technology, the detector can also cover the spacecraft entirely outside or just a certain critical part. It can be programmed to identify small or large damages and review the scope of damage.

In the future, the system also appears promising for calculating damage to the exteriors of airplanes or planned Martian habitats.

Recently, two ISS astronauts took a6.5-hour spacewalkto prepare the space laboratory for upgrades. Two more spacewalks arescheduled, on April 2 and 4, and will each feature two astronauts from Expedition 50.

NASA undertakes these efforts to keep its existing programs in top condition amid a financial battle with the Trump administration, which has almost officially canceled or allotted lower funding to platforms such as earth sciences and the Office of Education.